| No. | Item name | Parameters / Specifications |

| 1 | Main function | Longitudinal movement of two-axis actuator X-axis: Lateral movement of the spray head on the line rail Ø Y axis: manual adjustment of the upper and lower of the spray head Built-in automatic gluing program (the gluing track is customized by the customer, and the workpiece margin can be manually set) Automatic feeding system The left and right stations are automatically cleaned after gluing Rubber storage bucket with automatic heating function (customer-provided mold temperature machine) |

| 2 | Power supply | Voltage 380V/220V,50Hz |

| 3 | Maximum glue output | 8kg/min |

| 4 | Metering Pump | A Specification: GHZ-40 Brand: Taiwan B specification: ZPD-2.5 Brand: Germany |

| 5 | Metering pump motor | Brand: Siemens |

| 6 | Feed pump | A specification: high viscosity rotor pump Brand: Hebei B Specification: Diaphragm pump Brand: Shanghai |

| 7 | Range of gluing width | 0~2500mm |

| 8 | Positioning accuracy | ±5mm/10000mm |

| 9 | Low pressure foaming machine material tank | A volume: 500L pressure tank Brand: Shanghai B volume: 500L pressure tank Brand: Shanghai |

| 10 | Automatic cleaning tank | Volume: 18L Brand: Shanghai |

| 11 | Electronic control system | PLC independent control Brand: Siemens With overcurrent, overload, short circuit, lack of phase protection |

| 12 | Service life | Except for wearing parts, the design life of the equipment is ≥10 years |

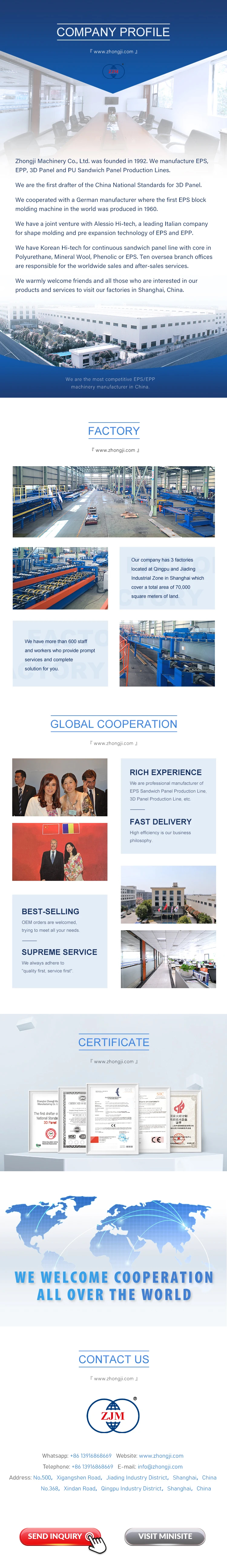

2.The company has a professional The Adjuster team, 24 hours to provide uninterrupted after-sales service.

(1) Installation and debugging

Equipment arrived at the customer workshop, according to the flat layout of our equipment. We will arrange experienced technicians to install, debug and test-produce the equipment, and make the equipment reach the rated production capacity of the production line.

(2) Training

Our company provides technical training for our customers. The training includes the structure and maintenance of the equipment, the control and operation of the equipment, experienced technicians will guide and establish the training program. After training, the buyer's technical personnel can master the operation and maintenance of the equipment, can adjust the process and deal with different failures.

3.After-sales quality problems within 2 hours to answer, if the telephone video guidance can not be solved, domestic 24 hours to send engineers to the site to solve the problem.

4. Factory direct sales price concessions, 40,000 square meters factory, 20 years of Export Enterprises, CE certification, patents more than 50 items.